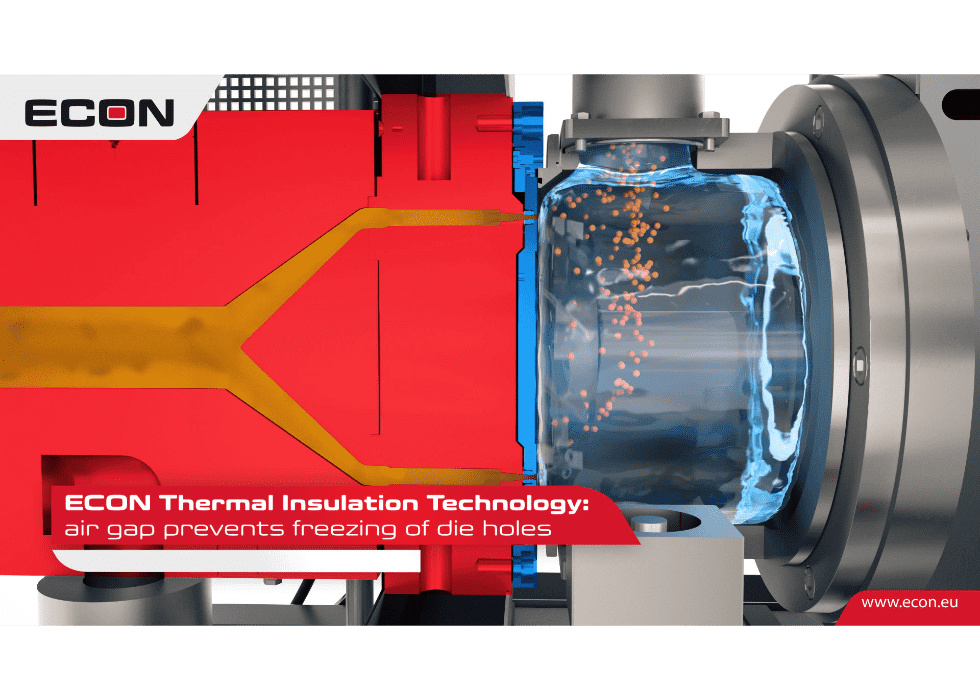

PATENTED THERMAL INSULATION

- no freezing of the die holes

- constant melt temperature over the complete length of the nozzle

- no overheating of the melt

- larger throughput range per hole (up to 1:8)

- minimal heat flow to the process water

- saves energy

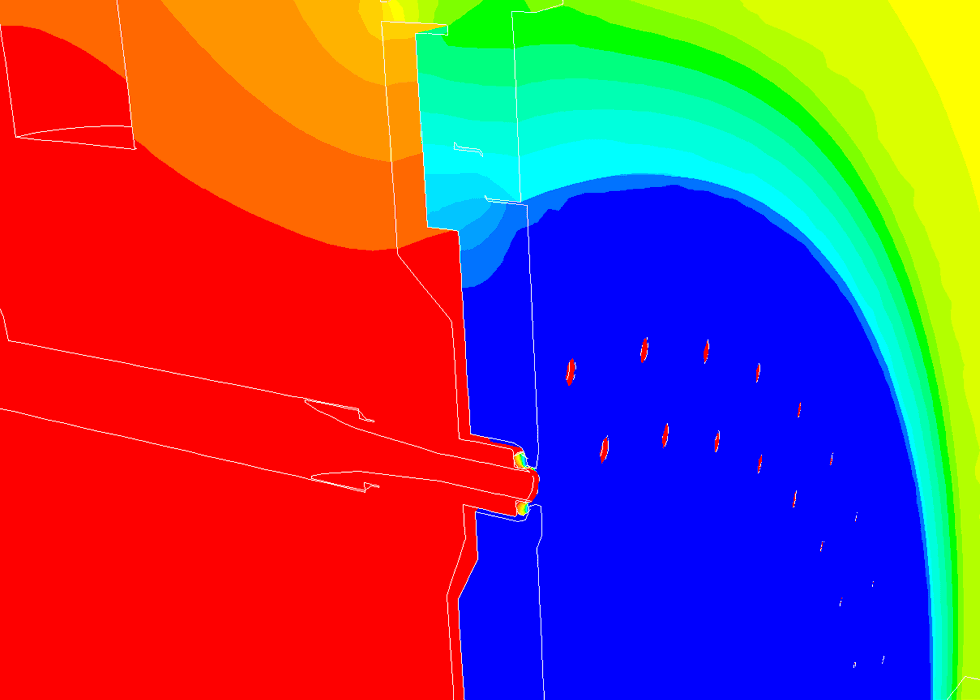

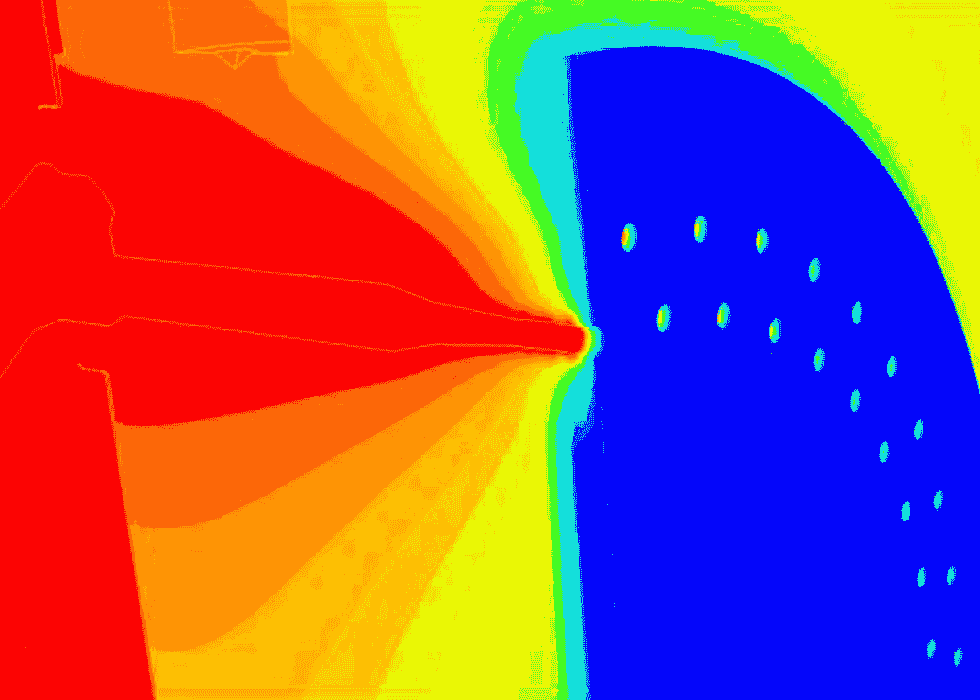

ECON: complete thermal insulation

ECON: complete thermal insulation

Competitors: Permanent energy transfer to the process water

Competitors: Permanent energy transfer to the process water

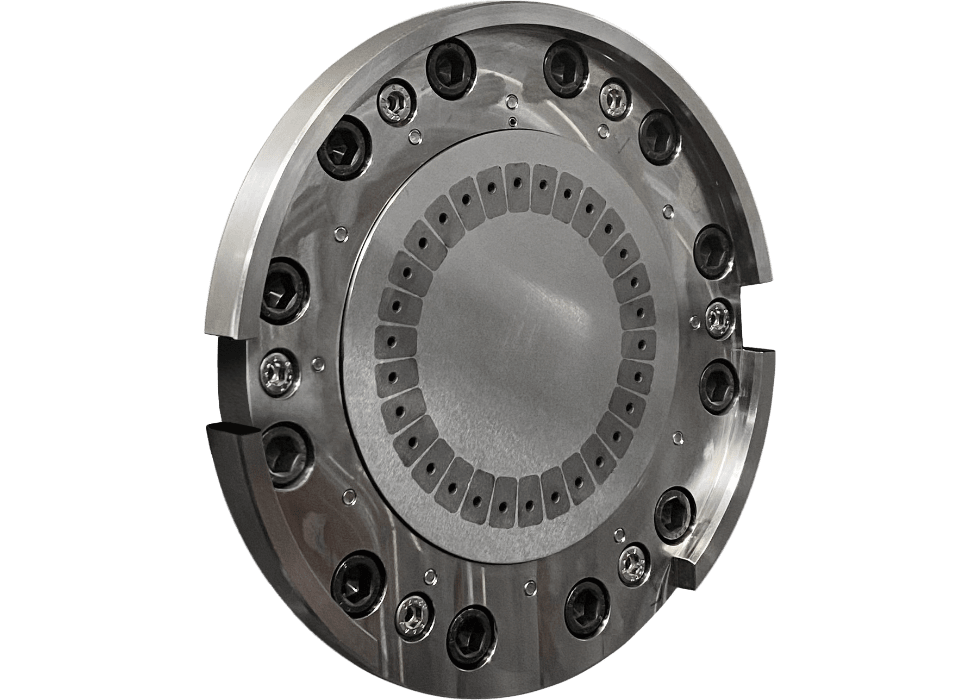

Easily accessible die plate unit

Easily accessible die plate unit

ECON: complete thermal insulation

ECON: complete thermal insulation

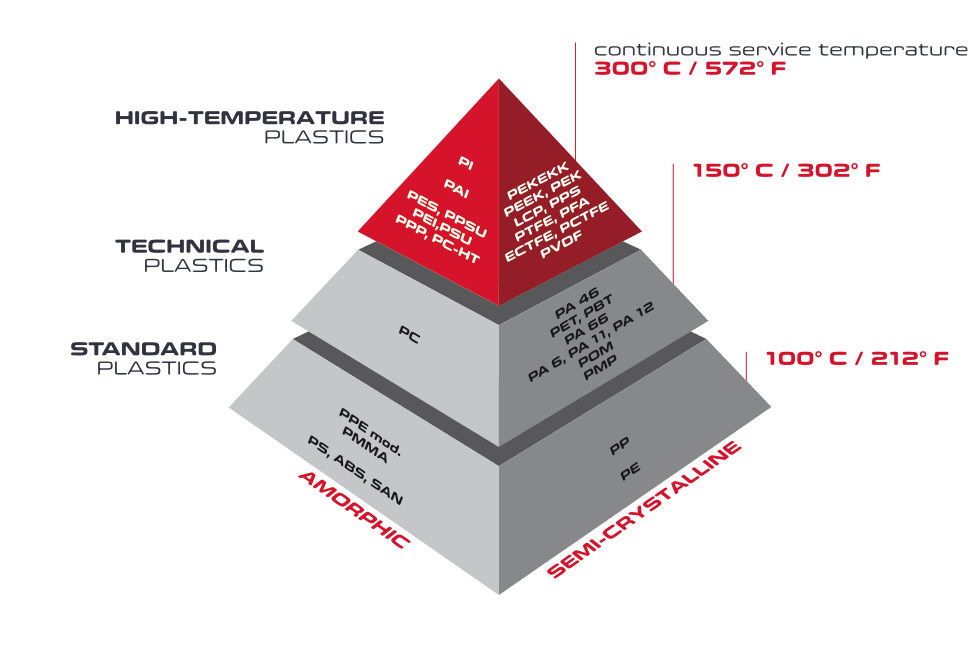

FOR ALL THERMOPLASTICS AND SPECIAL APPLICATIONS

The innovative technology of ECON makes the pelletizing of plastics possible where it could not otherwise be pelletized. By means of the patented thermal insulation, materials can be pelletized with high temperature requirements or high percentage of filled materials. Also, materials with a high melt flow rate.

- high temperature ranges

- compounds with high filler content

- high MFR (melt flow rate)

- rubber-like, adhesive and viscous materials

- micro pellets

Plastic information pyramid

Plastic information pyramid

Easy and safe operation

With the operation of ECON pelletizers, we combine two essential requirements: Easy to operate and safety of operator and machine. With the linear bearings, easy accessibility of the die plate, residue-free material change and hydraulic locking system, the ECON pelletizer concept guarantees easy and safe operation.

- easy and safe operation

- maximum process stability

- smooth, fast start-up process

- operational safety

ENERGY-EFFICIENT SOLUTIONS

Our Thermal Insulated die plate saves energy two ways. On the one hand, the process water is barely heated up by the patented thermal insulation, thus, less cooling energy is required. Furthermore, less extrusion pressure needs to build up less energy consumption and lower operating costs.

- minimal heating of the process water

- less cooling energy

- up to a ⅓ less extrusion pressure

- low heating power required

The ECON technical center continuously develops and researches.

The ECON technical center continuously develops and researches.

DEVELOPMENT AND INNOVATION

Continuous improvement processes, stimulated by employees and customers, are an essential component of our innovated management team. New developments are tested and proven in our technical center in Austria. We also offer our customers and prospective customers the opportunity to do a trial with their own material, engineered to their individual requirements, at all branches.

Are you not able to test your product at our branch? We bring the testing environment to you. Take advantage of our rental equipment offer!

ECON GmbH

Biergasse 9

4616 Weisskirchen/Traun

AUSTRIA

Phone: +43 7243 56560 0

Fax: +43 7243 56560 19

e-mail: office@econ.eu

Registration court Wels: FN 187941i

VAT no: ATU 47763102