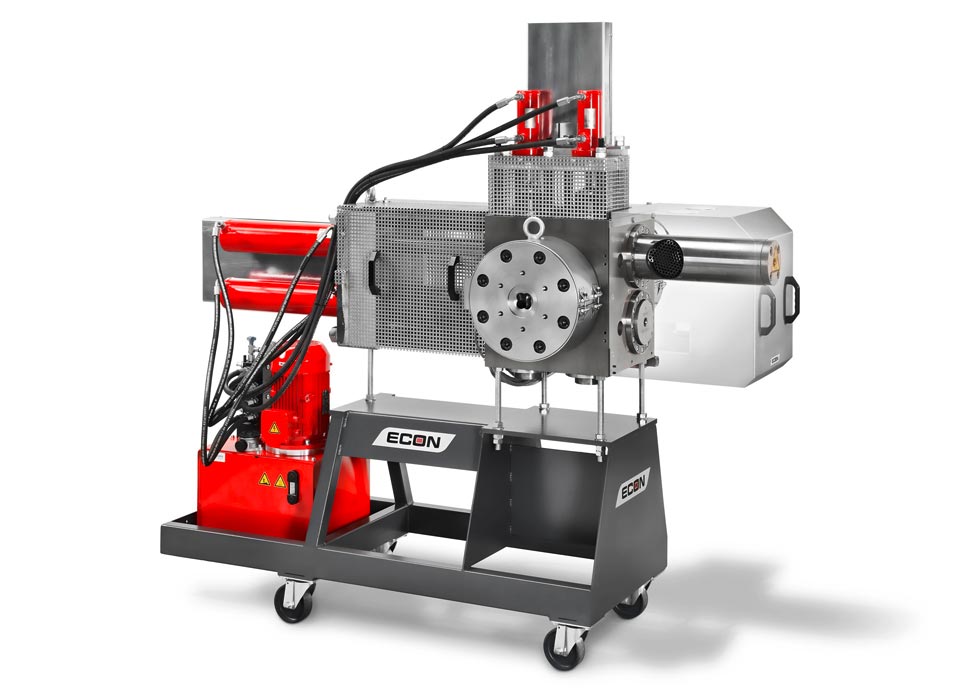

Continuous Screen Changer with Backflush System ESK B

The continuous double-piston screen changers with backflush system provide major advantages with their fully automatic cleaning of the screens as soon as a defined maximum pressure is met.

- all thermoplastic materials can be processed

- optimal design of the melt flow way - short melt residence time

- low pressure build up - to prevent thermal variations of the melt

- no dead spots for fast changes of material or color

- approx. 75 % effective screen area

- operational reliability and long durability

Continuous Screen Changer with Backflush System ESK B

Continuous Screen Changer with Backflush System ESK B

Function

The piston in the backflush unit redirects the melt flow, so only one piston with screens is currently being used in the production process. The other screen pack is flushed backwards, so any contaminants with only minimal melt are removed from the screens through the backflush unit. Afterwards the process is repeated with the other screen pack.

Types

The continuous screen changers with backflush system are available for throughputs up to 3,750 kg/hr.

ECON GmbH

Biergasse 9

4616 Weisskirchen/Traun

AUSTRIA

Phone: +43 7243 56560 0

Fax: +43 7243 56560 19

e-mail: office@econ.eu

Registration court Wels: FN 187941i

VAT no: ATU 47763102